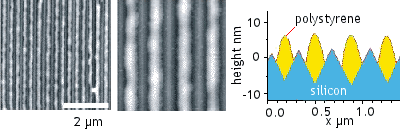

Above: The figure above left shows an SFM topography image of a 100 kDa polystyrene film after annealing for 3 h at 150°C. The lighter regions correspond to the polystyrene channels. Center - we show a magnification of part of this image, with average line scans revealing the cross-sectional morphology (right). The peaks in the silicon are free of polystyrene, which has migrated to the valleys.

Pattern formation is a very current topic. The behaviour of films on patterned substrates, or the creation of patterned structures may well have implications for modern lithographic processes, as well as providing substrates with nanoscale applications, such as providing templates for protein crystallography.

In this example, we used scanning force microscopy to study the stability of ultra-thin polystyrene films on structured silicon substrates. The silicon substrates were created using polished single crystal silicon cut slightly off the crystal axis. By high-temperature treatment, surface rearrangement takes place, and a corrugation is imposed. This corrugation has a periodicity of the order of 200 nm and an amplitude of the order of 6 nm. We spin-coated thin films of polystyrene of several nm thickness onto these substrates and annealed the films at elevated temperatures. If the film was thicker than about half the polymer radius of gyration, it was observed to be stable. If the film was thinner than half of the polymer size (radius of gyration), it dewetted into channels along the corrugations. Such a morphology suggests that confinement plays an important role in the dewetting [1, 2].

References

[1] N. Rehse, C. Wang, M. Hund, M. Geoghegan, R. Magerle, and G. Krausch Eur. Phys. J. E 4 69-76 (2001).

[2] M. Geoghegan, C. Wang, N. Rehse, R. Magerle, and G. Krausch J. Phys.: Condens. Matter 17 S389-S402 (2005).